Products

Yucera CAD CAM 5 Axis Zirconia Milling Machine For Dental Laboratory Glass Ceramic Composites Wax PMMA

Yucera CAD CAM Zirconia Milling Machine Glass Ceramic Composites Wax PMMA

Yucera CAD CAM Special Milling Machine Equipment Dental Zirconia Glass Ceramic Composites Wax PMMA YUC Mills 5000

Simple introduction for Yucera CAD CAM Special Milling Machine:

After 2 years of design and development,more than 100 labs tested, our Separation of mechanical and electrical control get unanimous praise

1. Horizontal processing-speed can be increased by nearly 20%

2. simplifying maintenance- When the all-in-one machine fails, the after-sales maintenance is more complicated. The split equipment only needs to replace the processing system to complete the update and maintenance;

3.Tool detection sensor with 2um

4.24hours on-line technical support

5.include hyperdent(free)

Technical Parameters of 5 axis cadcam dental milling machine:

| Axis | 5 Axis |

| Cut Method | dry milling |

| Milling Materials | zirconia block, pmma, wax, PEEK |

| Size of milling materials | φ98, thickness(10-30mm) |

| Range of rotation & tling rotation | x/y/z: 105 / 135/ 90 A:360° B:±30° |

| Speed of Principal axis | 0-60000rpm / 500w |

| Driver | Full rotation servo motor drive |

| cutters | 5 tools; φ4mm |

| size of dental 5aixs milling machine | CNC machine:55*56.5*46cm;Host milling machine:45*25*45cm |

| G.W: of dental 5aixs milling machine | CNC machine:95kg; Host milling machine:20kg |

| Compressed Air: | 4.5-7.5bar;50ml/min |

| Min Capacity-Dry: | 3000L/min |

| Power requirement : | 800W;220-230v AC,56/60 hz |

Brief Introduction Of 5 axis cadcam dental milling machine:

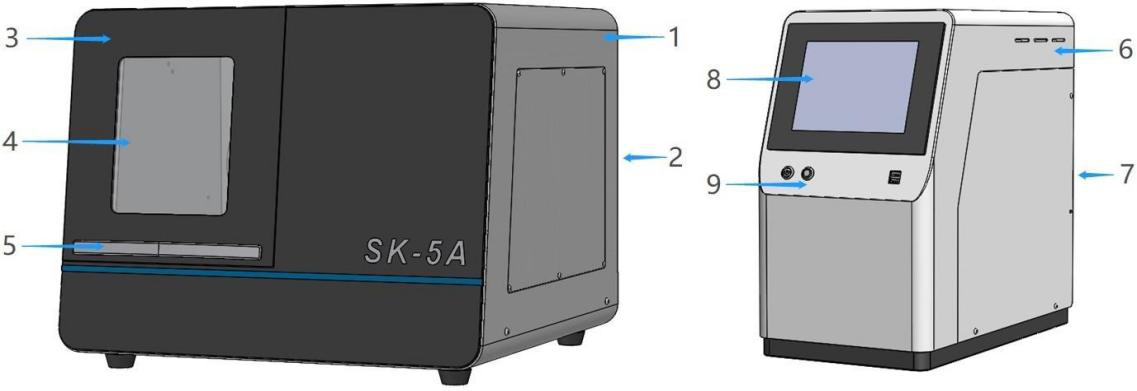

1. CUTTING MACHINE 2.CONNECTION PLATE ON BACK OF CUTTING MACHINE 3.THE HATCH 4.OBSERVE THE WORKING CABIN WINDOW

5. DOOR HANDLE 6.HOST 7.CONNECTING BOARD ON THE BACK OF THE HOST 8.DISPLAY SCREEN 9.OPERATION PANEL

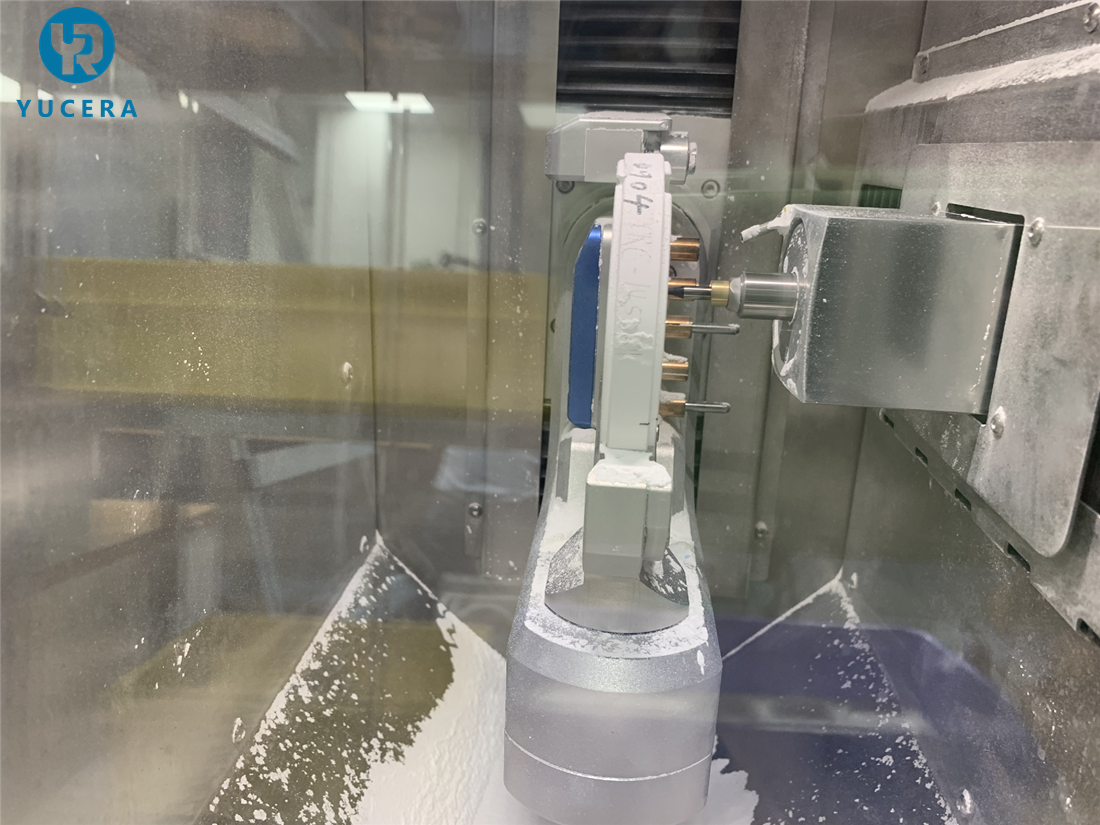

The SK-5A five-axis cutting machine is designed to facilitate digital processing in the field of dental technology and can handle different

types of materials.

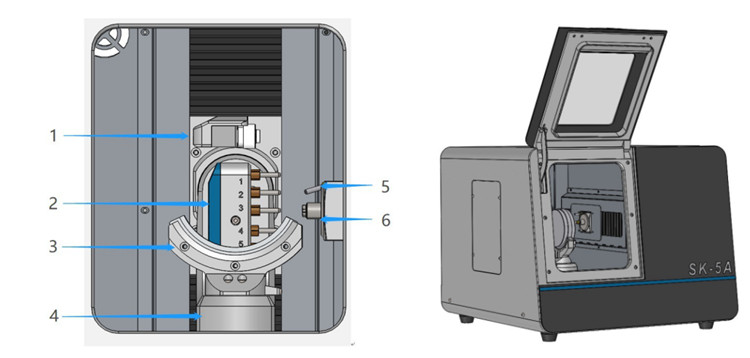

The Connection Board On The Back Of 5 axis cadcam dental milling machine:

1. BUTT JOINT WITH CUTTING MACHINE 2.NETWORK POT 3.POWER SWITCH

4. POWER CONNECTION 5.BUTT JOINT WITH HOST

6. BAROMETER 7.AIR INLET 8.VACUUM PORT

Working Hatch of 5 axis cadcam dental milling machine:

The working compartment door must be closed when the machine is working to prevent personnel from being injured. Note: Beware of pinch injuries when opening or closing the hatch

●When opening the door, hold the door handle with your hand and lift it up

●When closing the door, place your hand on the lower edge of the door and push it down

Package of 5 axis cadcam dental milling machine:

5-Axis Milling Machine with EVA foam wrapped in carton+ wood package 1PCS/Carton

FAQ:

1. A: How many pieces of units can mill?

Q: One piece zirconia block can be milled 50units crown.

2. A: What’s the toleance of the milling machine can reach?

Q: Our machine accuracy is 0.02mm. It’s suitable to match with oral scanner .It can mill directly without model. Save step and save time

3. A: How to deal with the dust after milling?

Q: The dust in the working cabin will not enter the control cabin, which in turn has a good guarantee for the service life of the circuit system. Outsourcing vacuum cleaner